Improving the Internal Setup Activities

The Fourth Stage of SMED

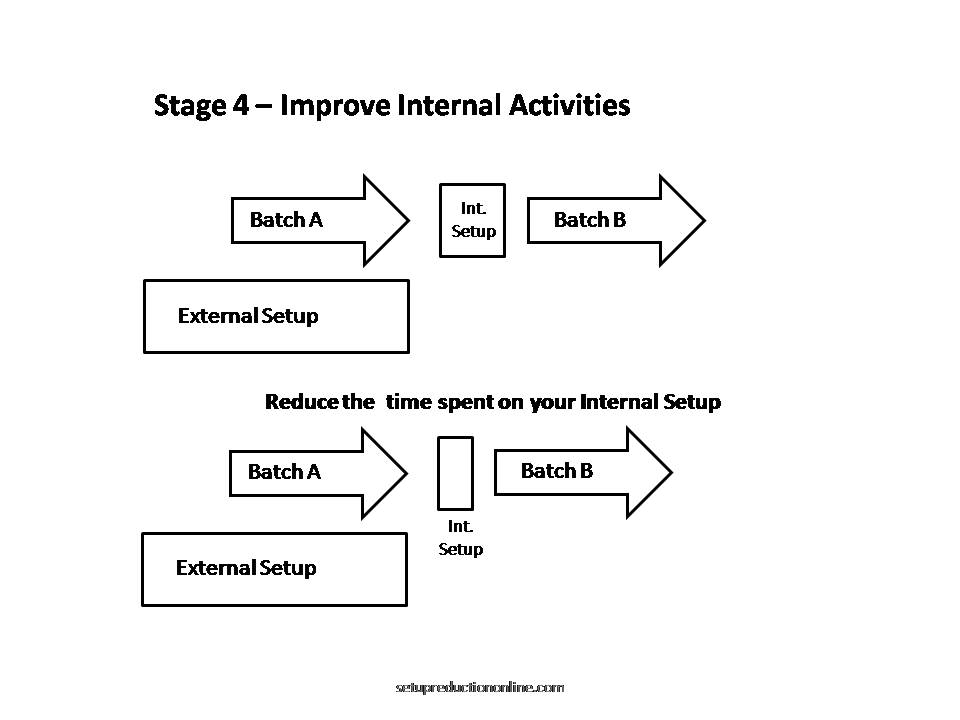

In the previous stages of our SMED implementation we have identified and separated the internal and external activities of our changeover, internal activities being those that have to be done while the machine is shut down and external being those that can be safely completed while the machine is still running. We have then gone through the internal setup activities to convert them to external activities. At this point we have probably managed to save around 75% of our setup time.

Why do we need to improve the internal setup time

Having managed to make significant improvements for our quick changeover we now need to look at improving those activities that must be performed while the process is actually idle. This is the point that most engineers want to jump to straight from the start; but if they did they would lose out on all of the savings that we have already made.

This stage will see us look at and begin to improve those activities that have to be undertaken while the machine is stopped, this will be the controlling factor in reducing our time further. This means looking at every stage of what we do and asking ourselves why we are doing it and if we can do it better.

How do we improve our internal changeover activities?

We already have our breakdown of the process from our previous steps; we now need to look at each individual step and ask ourselves firstly why are we doing it? Maybe we can skip the step or it should be part of our external setup and we have overlooked it within the previous stage.

If we have to do it as part of the internal setup we should ask ourselves who, where and when it needs to be done before we look at how.

- Is this the right stage of the setup to do it?

- Can it be done easier or quicker earlier or later in the process?

- Is this person the right one to undertake the activity?

- Is there scope for more than one person to conduct the changeover?

- Is it being done in the right place?

- Can it be done quicker from elsewhere?

- Then we need to ask ourselves are we doing it in the right way?

- Is there a quicker more efficient way to do this?

Examples of SMED improvements

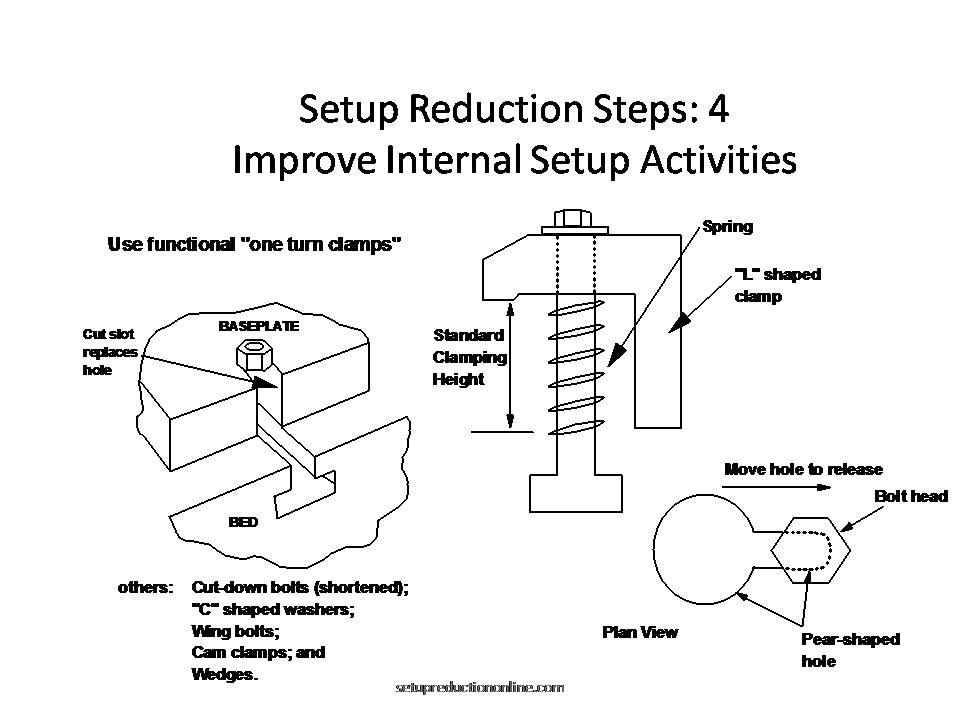

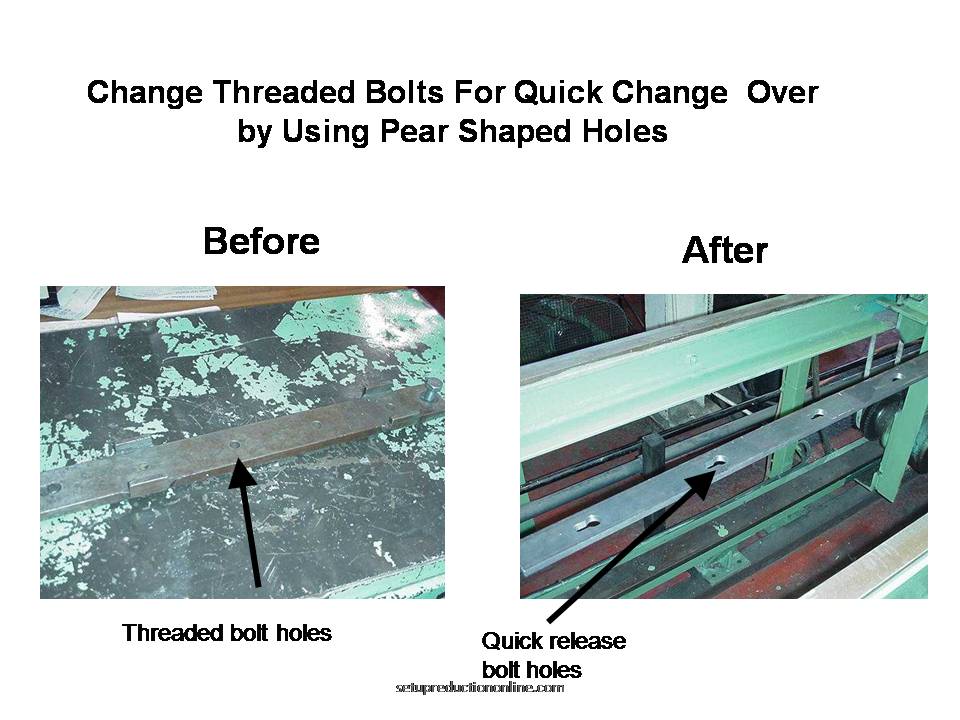

One of the commonest things that delays all setups is the use of bolts and screws to fix jigs and fixtures, as Shigeo Shingo once said; “only the last turn of the bolt tightens, the rest is motion (waste).” How often have you seen a setter struggling with an spanner to tighten a bold for a minute or more and then repeating it a dozen more times.

To eliminate the waste of tightening bolts there are a number of options that we can implement; these can range from boltless clamping using toggle clamps or offset cam levers through to pear shaped holes that can be slid over bolts and then only need a single turn to tighten.

The pictures below shows several options that you could use;

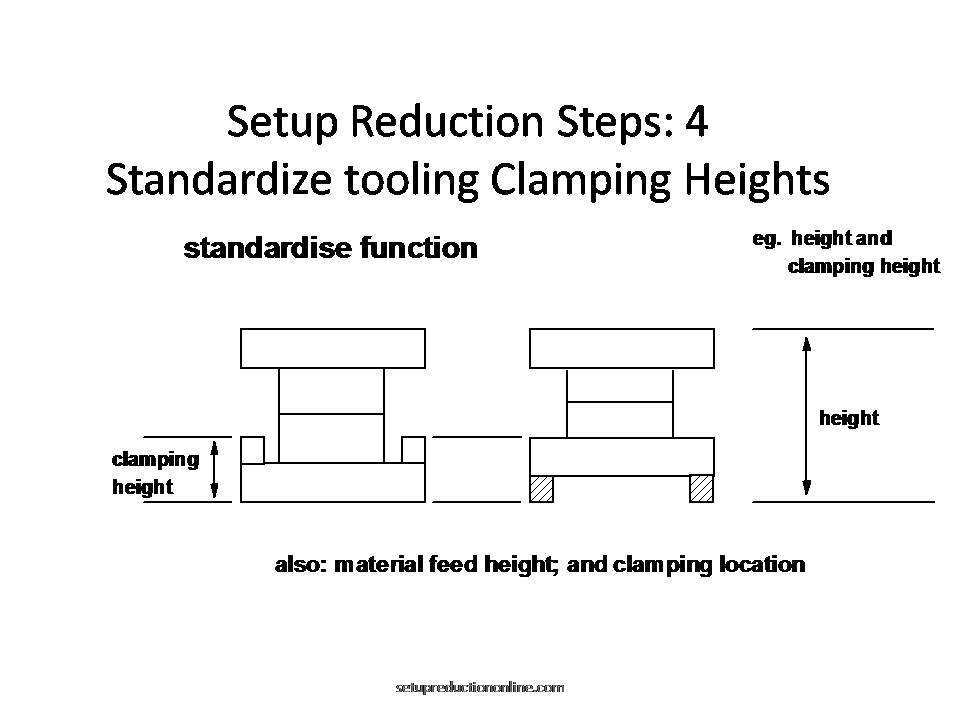

Many setups also require the use of measurement or careful adjustment to set things such as guides or to position tools just right; these should instead be done through physical pinned locations or by using setting jigs or spacers so that there is no need to use measurements.

Standardize Your Internal Setup Activities

Machine and process settings should also be recorded so that you have a set baseline from which to start the process each time rather than relying on the memory of the setters. You will often find that different operators or setters will have different settings that they use and these should be standardized. Again update your operating and changeover instructions at the end of this stage to ensure that everyone understands what they should do and that the time savings you have gained are maintained.

Rinse and Repeat

We are aiming here for a quick changeover that is less than 10 minutes in length, if we have not yet achieved this then before we look at the later stages we should repeat this process until the team feels that they have exhausted all possible solutions. If necessary bring in new team members to provide a fresh set of eyes on your setup process.

Improve External Activities

We should now have improved the internal setup activities significantly compared to where we were when we first started our SMED implementation. However we now need to go and take another look at our external setup activities as we will probably find now that they are more time consuming than the rest of the setup. You will find the next stage of our single Minute Exchange of Die implementation by clicking the link to our final SMED Stages to improve external setup, implement automation and eliminate changeover completely.