The Final Stages of our Quick Changeover Implementation

SMED Stages 5 to 7

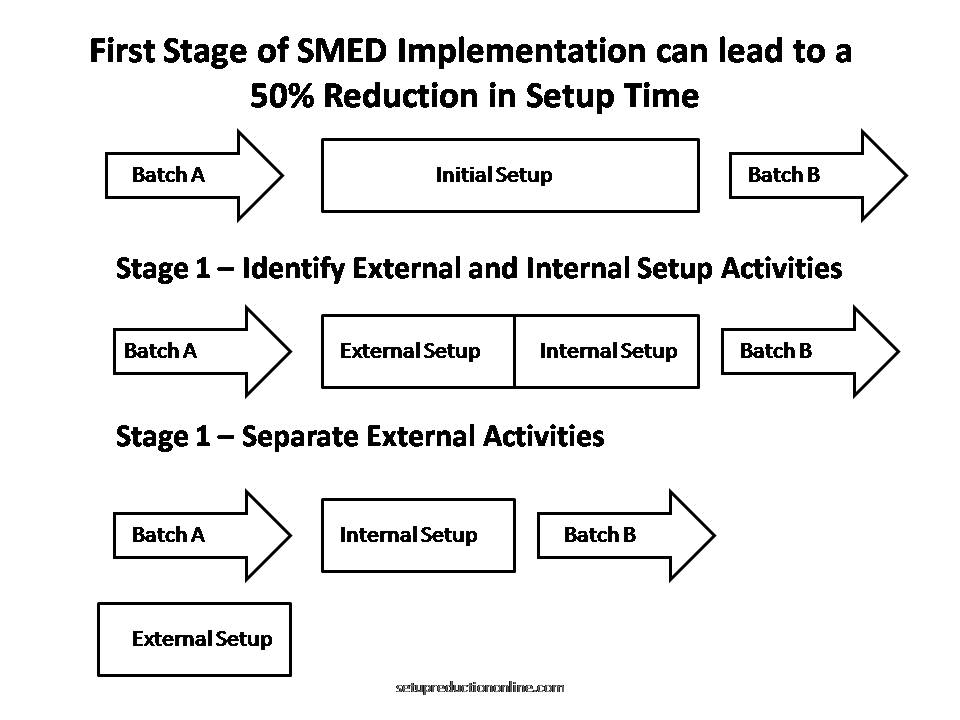

I will deal with the final stages of SMED in one single post as these stages are fairly simple and related. We have already by now significantly reduced our Setup, hopefully already down to single minutes. The aim of SMED or Single Minute Exchange of Die is to get the changeover down to less than 10 minute.

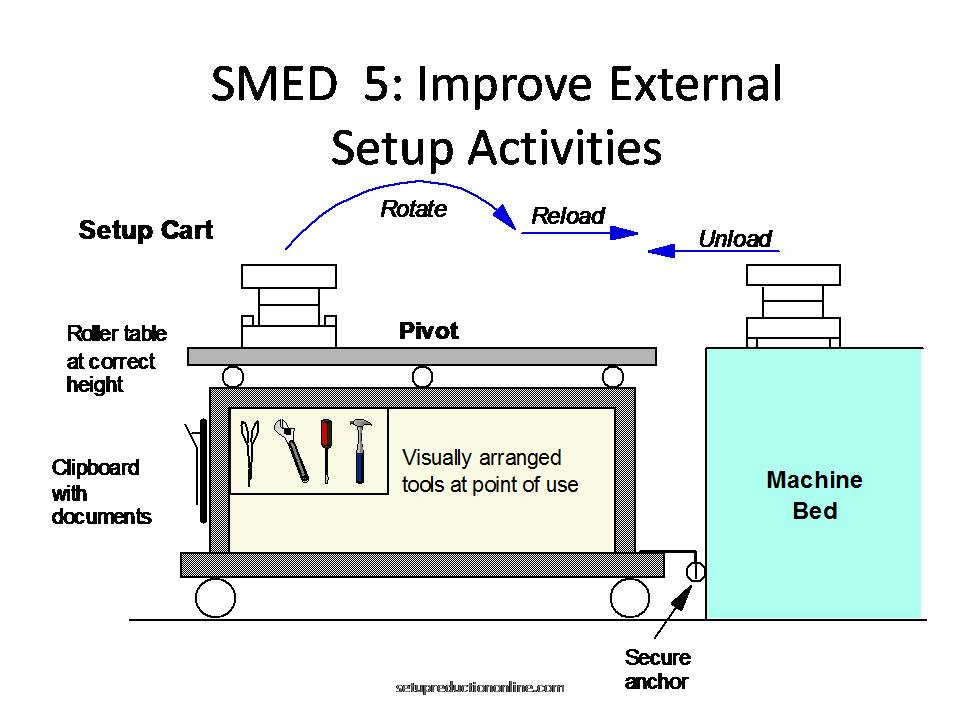

SMED Stage 5;

Improve External Activities

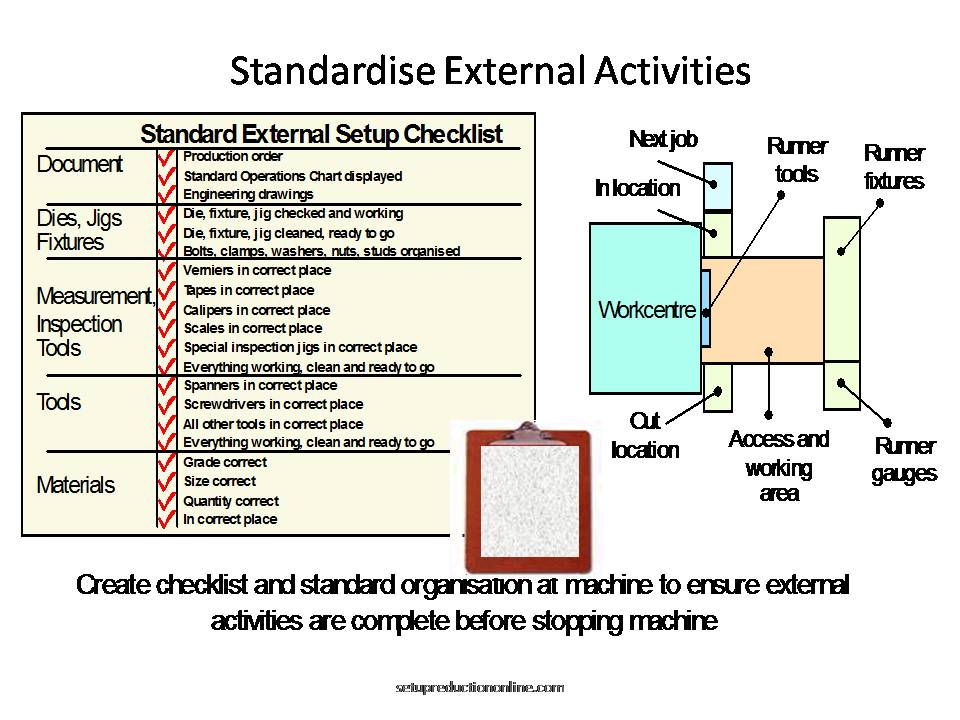

You will probably be at a stage now where the activities that are performed while the process is still running take longer than the actual quick setup process that you now have. This should be worked on using the same ideas that you have already used for your internal activities to ensure that you reduce the time that is spent on these external activities;

- Look at 5S principles on your external setups

- Look at who is performing the activities

- Look at where the activities are being done

- Look at easier ways to actually perform the activity

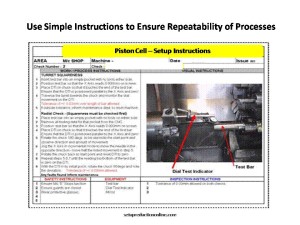

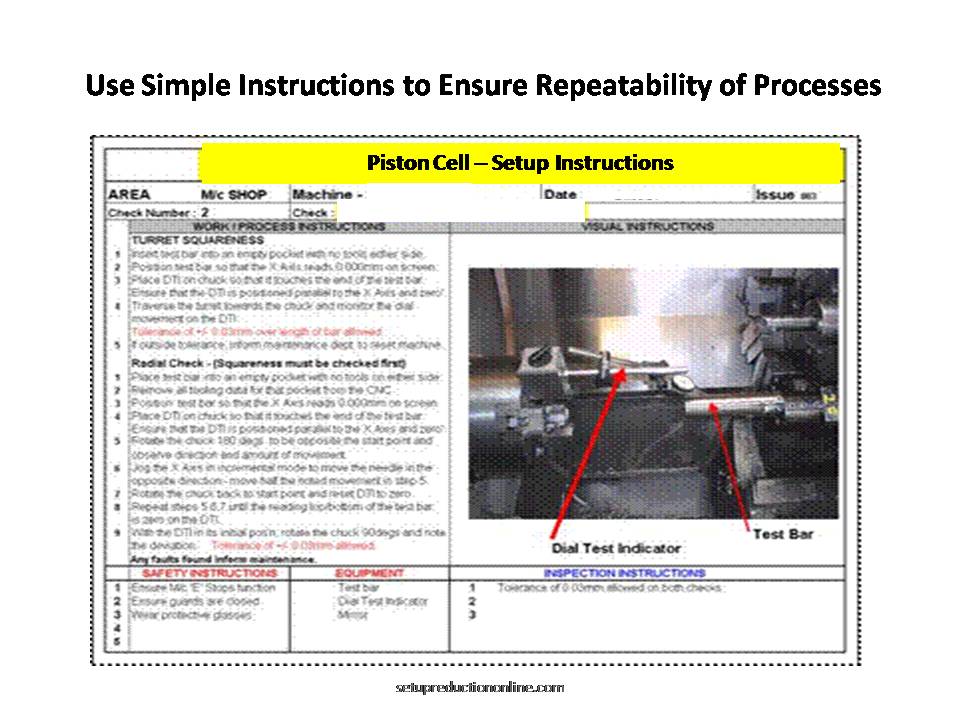

Once you have reduced your external activities once again ensure that your process if fully documented to ensure that everyone follows best practice at all times. You do not want to have differences between different operators or shifts.

SMED Stage 6

Automate Change Over

Automation is rarely a cheap option which is why this is one of the final steps of your SMED implementation. In most cases you will be able to reduce a setup to less than 10 minutes without the use of any form of automation.

Before embarking on any form of automation you should very carefully consider the cost benefits of what you will do as well as the final step of our quick change over program which is to actually eliminate the changeover completely. If the cost benefits are not going to justify using automation you should revisit the previous steps of your Single Minute Exchange of Die program to see if you can achieve any additional changes.

The other reason for Automation is of course safety is you are handling heavy or hazardous materials in which case automation is a very valid way of moving forward.

I have rarely seen the need for a changeover to be automated, the few times that it has been automated it has come with automated loading and unloading of components so people have actually been freed from the process to conduct other work within the process.

SMED Stage 7

Eliminate The Changeover

The ultimate changeover reduction is of course to eliminate the entire setup. If there is no need for a changeover then you will waste no time. This can be achieved through the following simple ways;

Have dedicated machines; often it is cheaper to have many smaller dedicated machines than one all singing all dancing super machine that does everything.

Design Modifications; remove the need for multiple components through the design process

Modify tooling to produce multiple parts; consider an “airfix” style injection molding tool that produces a whole set of components rather than multiple sets of one component.

Like automation eliminating the setup can be an expensive and often time consuming option so it is something that will require a cost benefit analysis.

Feedback your SMED Learning Into Your Design Process

It is always best to try and include members of your design teams into your SMED implementations so that they fully understand the results of some of their choices and are able to feedback what they learn into future designs. Far better to be able to start a new product with no changeovers or changeovers that are already in single minutes.

Help With Your SMED Implementation

If you are having any problems with your quick changeover process feel free to contact us here for help and advice in ensuring that you achieve your setup goals. If you feel that any of the information here is unclear or you would like to add anything then feel free to use the contact page to get in touch.