Converting Internal Changeover Activities into External Changeover Activities

Third Stage of our SMED Implementation

If you have got this far with your SMED implementation then you will have probably shaved at least 50% off of your changeover and will be eager to achieve more. In the first stage we separated our internal and external changeover activities allowing us to ensure that all of the external activities were already completed prior to us actually stopping the process. This included things as simple as finding tooling and having everything to hand before we actually started the quick changeover, things that many would say should be common sense but still failed to implement before.

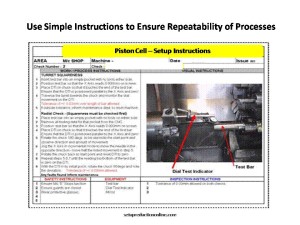

The second stage saw us standardize external setup elements ensuring that not only do we have a quicker changeover but that it is done repeatably and also preventing the creep back to where we were before; something that always tends to occur if we don’t document our new ways of working.

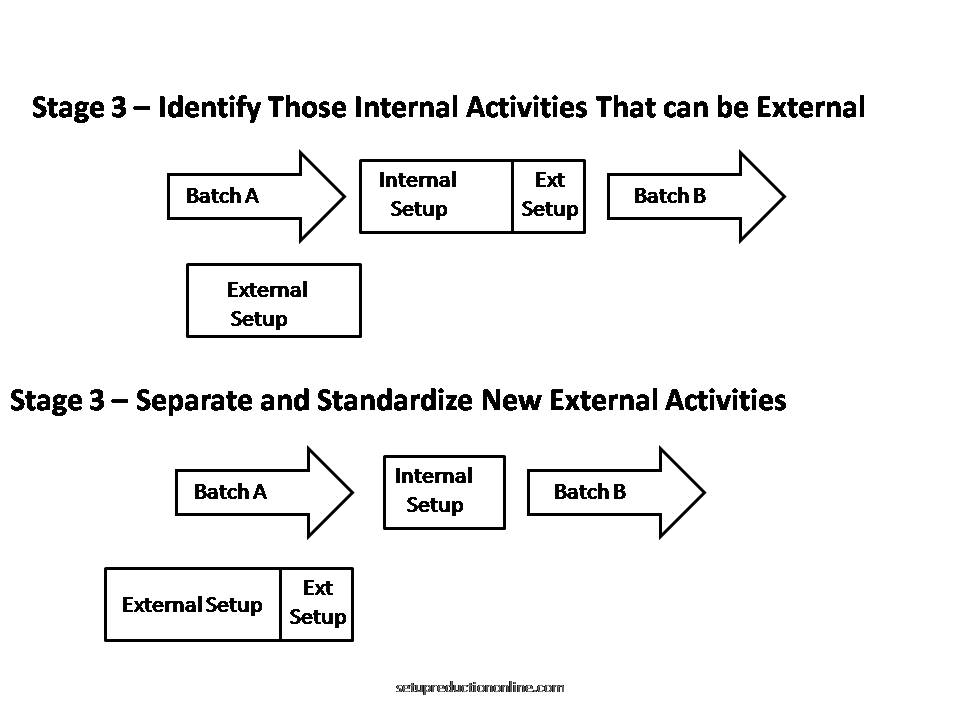

The next step is to look at all of the internal setup activities and consider how we can convert them into external activities allowing us to further reduce the actual down time of the process while we setup.

Why do we need to convert internal setup activities into external?

(Why Improve Something if you Don’t Need to do it!)

The Internal activities have to be done while the process is at a standstill, so obviously we are seeking to minimize this time. The engineers amongst you will be keen at this point to jump in and to try to make every stage of our changeover easier and quicker but you need to ask yourself first does this step even need to be done as an internal step? Is there a way that we can convert this step into an external activity that can be done while the process is still running? We need to see if we can remove some of these internal changeover steps rather than just trying to make them quicker. Often by the time we get to the end of this third stage it is not unusual to have eliminated 75% or more of the original setup time.

What sort of activities can be converted?

The following is a list of common activities that could be modified in some way so that they can be done while the process is still running;

- Preset cutters within a tool using fixtures so that they are ready to use

- Use intermediate jigs allowing dies and fixtures to be mounted and adjusted prior to fitting

- Preheating of Dies /materials (Formula one tires are heated to race temperature before fitting)

- Additional set of changeover parts available pre-cleaned rather than having to clean and re-use what is currently in use.

If you find something that is not on the list then do it and let us know.

Standardize your new external activities

Once you have your new external activities ensure that you add them to your check sheets and standardized ways of working that you produced in the second stage of our SMED implementation. Far too often people get carried away with the success of making so many improvements that they forget to document everything and six months later things have drifted right back to where you started.

Improving Internal Changeover Time

The next stage of SMED is to look at improving the internal changeover activities themselves and to see what can be improved to further reduce the time for our quick changeover. So our next stage is to improve internal setup activities for SMED.